O-Rings are one of the most common types of seals in the world. With an unlimited number of possible manufacturing sizes, they are used for an array of applications in many different industries. These round mechanical seals keep gas or liquid from passing through an opening but over time, they may wear out and require replacement. If you’re planning to replace an O-ring, a good fit is critical for successful sealing. Below are the steps to take to properly measure for a new or replacement O-Ring (O-rings are measured in millimeters).

O-Rings are one of the most common types of seals in the world. With an unlimited number of possible manufacturing sizes, they are used for an array of applications in many different industries. These round mechanical seals keep gas or liquid from passing through an opening but over time, they may wear out and require replacement. If you’re planning to replace an O-ring, a good fit is critical for successful sealing. Below are the steps to take to properly measure for a new or replacement O-Ring (O-rings are measured in millimeters).

How to Measure O-Rings: Step-by-Step

- Place the O-ring on a clean, flat, level surface.

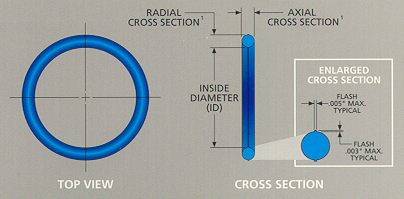

- Determine the inside diameter by using a ruler to measure from one inner edge to another.

- To measure the outside diameter, use a ruler to measure from one outer corner of the O-ring to the other outer corner.

- Finally, measure the cross-section. Place the O-ring into a vernier caliper. Lightly clamp the jaws of the caliper onto the O-ring, but do not compress it. Record the thickness of the ring (the cross-section).

O-Rings for Lots of Things

O-Rings have a long list of standard sizes that can be used across various industries and geographic regions. Now that you know how to measure O-rings properly, download our O-Ring Size Chart to view standard sizes. If you would like more information or to place an order, contact us today!